our branch

Wuxi Zhongyue Petrochemical Equipment Co., Ltd.

Hubei Xianglong Chemical Equipment Engineering Co., Ltd.

Hongda Steel Im& Ex Co., Ltd.

HOT NEWS

-

Industrial waste gas treatment recovery unit solution

-

How to filter and dry three-in-one equipment

-

Industrial waste gas pollution hazards and treatment

-

Jinjiang Chemical 100,000 tons / year n-butyl acrylate cooperation project

-

Electroplating wastewater treatment

-

What are the classifications of industrial wastewater?

-

Microbial treatment technology for industrial waste gas

-

Zero discharge treatment technology for desulfurization wastewater

-

High concentration ammonia nitrogen wastewater treatment technology

-

Factors affecting the treatment of waste gas in the chemical industry

Concentrated evaporation equipment

Position:HOME > PRODUCTS >Pharmaceutical and chemical equipment > Concentrated evaporation equipment >

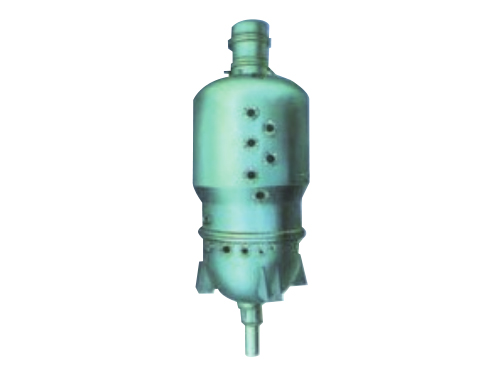

Multi-effect evaporator

Multi-effect evaporation is an evaporation operation in which several evaporators are operated in series, so that the steam heat energy can be used multiple times, thereby improving the utilization of heat energy, and is mostly used for the treatment of aqueous solutions. In the flow of the three-effect evaporation operation, the first evaporator (called the first effect) uses the raw steam as the heating steam, and the other two (called the second effect and the third effect) use the former steam acts as a heating steam, thereby greatly reducing the amount of steam generated. The secondary steam temperature of each effect is always lower than that of the heated steam, so the operating pressure of each effect and the boiling temperature of the solution in the multi-effect evaporation are sequentially decreased in the steam flow direction. According to the flow direction of the secondary steam and the solution, the multi-effect evaporation process can be divided into:

1. Parallel flow process. The solution and the secondary steam pass through each other in the same direction. Since the pre-effect pressure is higher than the after-effect, the feed liquid can flow by the pressure difference. However, the concentration of the final solution is high and the temperature is low, and the viscosity of the solution is large, so the heat transfer coefficient is low.

2. Counter flow process. The solution is in the opposite direction to the secondary vapor flow. The pump is required to send the solution to the previous effect with higher pressure. The effect of the concentration and temperature of each effect solution on the viscosity is roughly offset, and the heat transfer conditions of each effect are basically the same.

3. Cross-flow process. The secondary steam passes through each effect in turn, but the feed liquid enters and exits separately for each effect. This procedure is applicable to the liquid solution with crystal precipitation.

1. Parallel flow process. The solution and the secondary steam pass through each other in the same direction. Since the pre-effect pressure is higher than the after-effect, the feed liquid can flow by the pressure difference. However, the concentration of the final solution is high and the temperature is low, and the viscosity of the solution is large, so the heat transfer coefficient is low.

2. Counter flow process. The solution is in the opposite direction to the secondary vapor flow. The pump is required to send the solution to the previous effect with higher pressure. The effect of the concentration and temperature of each effect solution on the viscosity is roughly offset, and the heat transfer conditions of each effect are basically the same.

3. Cross-flow process. The secondary steam passes through each effect in turn, but the feed liquid enters and exits separately for each effect. This procedure is applicable to the liquid solution with crystal precipitation.

When the raw steam temperature is the same as the final effect condenser temperature (that is, the total temperature difference is the same), when the single-effect evaporation is changed to multi-effect evaporation, the evaporator efficiency increases, the raw steam consumption decreases, but the total evaporation does not increase. On the contrary, it has decreased due to the increase in temperature difference loss. Multi-effect evaporation saves energy, but reduces the production intensity of the equipment, thus increasing equipment investment. In actual production, energy consumption and equipment investment should be considered comprehensively, and the best effect should be selected. Evaporation of electrolyte solution such as caustic soda, due to its large temperature difference loss, usually only uses 2~3 effect; non-electrolyte solution such as sugar, the temperature difference loss is small, 4~6 effect can be used; the amount of water evaporated by seawater desalination is large, After various measures to reduce the temperature difference loss, 20 to 30 effects can be used.