our branch

Wuxi Zhongyue Petrochemical Equipment Co., Ltd.

Hubei Xianglong Chemical Equipment Engineering Co., Ltd.

Hongda Steel Im& Ex Co., Ltd.

HOT NEWS

-

Industrial waste gas treatment recovery unit solution

-

How to filter and dry three-in-one equipment

-

Industrial waste gas pollution hazards and treatment

-

Jinjiang Chemical 100,000 tons / year n-butyl acrylate cooperation project

-

Electroplating wastewater treatment

-

What are the classifications of industrial wastewater?

-

Microbial treatment technology for industrial waste gas

-

Zero discharge treatment technology for desulfurization wastewater

-

High concentration ammonia nitrogen wastewater treatment technology

-

Factors affecting the treatment of waste gas in the chemical industry

Concentrated evaporation equipment

Position:HOME > PRODUCTS >Pharmaceutical and chemical equipment > Concentrated evaporation equipment >

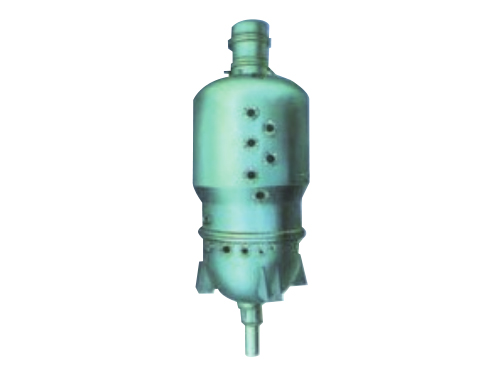

Vacuum concentrated crystal pot

The whole equipment can be divided into four parts: heating evaporation chamber, heating jacket, vapor-liquid separator and agitator. Based on the jacket heating, our factory has designed the internal heating and internal circulation heating, and the evaporation crystallization pot reflects the evaporation effect 1.8 times higher than the external heating (jacket heating).

The equipment and the product have contact parts, which are all made of 1 Cr18Ni9Ti, and the heating evaporation chamber, such as a cylindrical shell, is convenient for installation and maintenance, and is processed in two sections by different thickness materials, and is connected by flanges. The back cover can be processed into a hemispherical, dish-shaped, or conical body, and the lower cylinder is equipped with a sight glass to observe the boiling condition of the solution, the height of the entrainment of the mist, the concentration of the solution, the crystal size and distribution, etc.; The hole is for the convenience of cleaning and maintenance, and the lower pot is welded to the heating jacket, and the height is determined by calculating the required area for evaporation.

At present, the anchor stirrer is mostly used, the speed is 6-15 rpm, and the stirring is installed by the lower shaft, which can shorten the length of the shaft and facilitate installation and maintenance.

The equipment and the product have contact parts, which are all made of 1 Cr18Ni9Ti, and the heating evaporation chamber, such as a cylindrical shell, is convenient for installation and maintenance, and is processed in two sections by different thickness materials, and is connected by flanges. The back cover can be processed into a hemispherical, dish-shaped, or conical body, and the lower cylinder is equipped with a sight glass to observe the boiling condition of the solution, the height of the entrainment of the mist, the concentration of the solution, the crystal size and distribution, etc.; The hole is for the convenience of cleaning and maintenance, and the lower pot is welded to the heating jacket, and the height is determined by calculating the required area for evaporation.

At present, the anchor stirrer is mostly used, the speed is 6-15 rpm, and the stirring is installed by the lower shaft, which can shorten the length of the shaft and facilitate installation and maintenance.

|

Nominal capacity (L) |

Cylinder height (H) |

Cylinder diameter (Dg) |

Jacket diameter (Dg) |

Rotating speed (r.p.n) |

Power (kw) |

| 3 | 1700 | 1300 | 1400 | 6-15 | 5.5 |

| 4 | 2400 | 1400 | 1500 | 6-15 | 5.5 |

| 5 | 1800 | 1500 | 1700 | 6-15 | 7.5 |

| 6 | 3000 | 1800 | 2000 | 6-15 | 7.5 |

| 8 | 3000 | 1800 | 2000 | 6-15 | 10 |

| 10 | 3200 | 1800 | 2000 | 6-15 | 13 |

| 11.2 | 3200 | 2000 | 内加热 | 125-350 | 15 |