our branch

Wuxi Zhongyue Petrochemical Equipment Co., Ltd.

Hubei Xianglong Chemical Equipment Engineering Co., Ltd.

Hongda Steel Im& Ex Co., Ltd.

HOT NEWS

-

Industrial waste gas treatment recovery unit solution

-

How to filter and dry three-in-one equipment

-

Industrial waste gas pollution hazards and treatment

-

Jinjiang Chemical 100,000 tons / year n-butyl acrylate cooperation project

-

Electroplating wastewater treatment

-

What are the classifications of industrial wastewater?

-

Microbial treatment technology for industrial waste gas

-

Zero discharge treatment technology for desulfurization wastewater

-

High concentration ammonia nitrogen wastewater treatment technology

-

Factors affecting the treatment of waste gas in the chemical industry

Fermentation Equipment

Position:HOME > PRODUCTS >Pharmaceutical and chemical equipment > Fermentation Equipment >

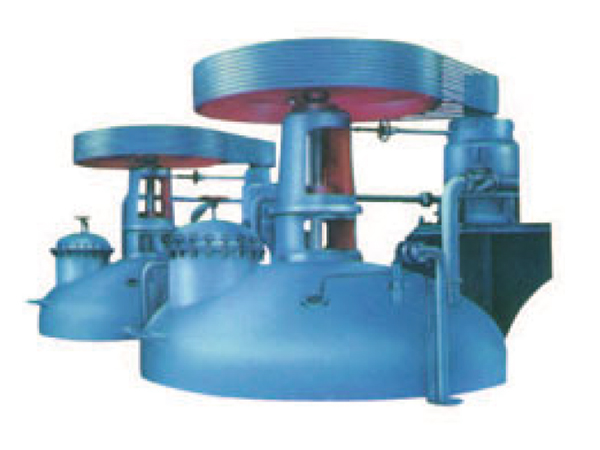

Fermenter, Seed tank

|

|

The fermentation equipment room is widely used for opinion reaction equipment for microbial growth. Various microorganisms are grown in the fermenter in a suitable environment, metabolism and fermentation products. Fermentation equipment has been widely used in the pharmaceutical, monosodium glutamate, enzyme preparation, food and other industries.

Fermentation equipment tank types can be divided into two categories. One type is a tank type that is anaerobic fermentation (such as alcohol fermentation), and the other type is a tank type (such as standard type, wood type, self-priming type, etc.) for gas fermentation. This type of equipment is most commonly used in standard tank types. The drawings of the fermenter series designed by our factory belong to the standard tank type. When designing various types of fermentation equipment, the design structure is strict, there is sufficient strength and service life, and the internal accessories of the equipment are less, the surface is light and slippery, and it is noted that there is good solidification and performance of the jujube steam contact and the jujube. The substance is transferred and the gas exchange is carried out efficiently. There is sufficient heat exchange area to ensure that the fermentation can be carried out at the optimum temperature. Pay attention to the sealing performance of the equipment to ensure sterilization operation.

The fermenter designed by our factory is a standard tank type. When the nominal volume is below 6m3, the tank is jacketed. The cooling or heating of the fermentation gas is accomplished by a jacket. When the nominal volume is 6 m3 or more, the cooling of the fermentation gas is carried out by the vertical pipe, and we have improved the connection of the pipe in the tank. This mainly avoids opening more holes in the tank and opening a dead angle. This continuous mode achieves satisfactory results in practical use.

The baffle provided in the tank is used to improve the mixing efficiency. The presence or absence of the baffle in the tank directly affects the condition of the fermentation steam turning. Therefore, it is very important to install the baffle in the tank. According to the relevant information, the number of baffles installed is increased or decreased. According to the measured data of the change in the width of the leaf, four or six baffles are used in the tank, and the width of the plate is from 1/12 to 1/10, which is most ideal for improving the stirring efficiency.

The king of the agitator-type fermentation equipment is required to stir the vapor body to mix the fresh medium components, air and mycelium to achieve the mass transfer and heat transfer effect. At present, there are three basic forms of agitators: flat leaves (straight leaves), curved leaves, and arrow leaves. The curved leaves are used in the equipment provided by our factory. The curved-blade worm wheel agitator has a shearing effect on the fermentation steam, and the fermentation steam flows in the axial direction and the axial direction. Compared with the straight-blade worm wheel agitator, the curved blade is stirred under the same diameter, rotation speed, and leaf width. The power consumed by the device is small, but the effect is very good, and it has been widely adopted in China.

In terms of motor configuration, we use Y-type motors (horizontal type) and YJL type motors (vertical type). Vertical motors are usually used for nominal volumes below 15 m3. Horizontal motors can also be used.

The tank topping is also very important for the fermenter. According to our experience over the years, the design of the take-over position is reasonable, and the operation of the workers is convenient. The size of the take-over is calculated. If the user has specific requirements, it can be negotiated. For special specifications, our factory can be designed separately.

Fermentation equipment tank types can be divided into two categories. One type is a tank type that is anaerobic fermentation (such as alcohol fermentation), and the other type is a tank type (such as standard type, wood type, self-priming type, etc.) for gas fermentation. This type of equipment is most commonly used in standard tank types. The drawings of the fermenter series designed by our factory belong to the standard tank type. When designing various types of fermentation equipment, the design structure is strict, there is sufficient strength and service life, and the internal accessories of the equipment are less, the surface is light and slippery, and it is noted that there is good solidification and performance of the jujube steam contact and the jujube. The substance is transferred and the gas exchange is carried out efficiently. There is sufficient heat exchange area to ensure that the fermentation can be carried out at the optimum temperature. Pay attention to the sealing performance of the equipment to ensure sterilization operation.

The fermenter designed by our factory is a standard tank type. When the nominal volume is below 6m3, the tank is jacketed. The cooling or heating of the fermentation gas is accomplished by a jacket. When the nominal volume is 6 m3 or more, the cooling of the fermentation gas is carried out by the vertical pipe, and we have improved the connection of the pipe in the tank. This mainly avoids opening more holes in the tank and opening a dead angle. This continuous mode achieves satisfactory results in practical use.

The baffle provided in the tank is used to improve the mixing efficiency. The presence or absence of the baffle in the tank directly affects the condition of the fermentation steam turning. Therefore, it is very important to install the baffle in the tank. According to the relevant information, the number of baffles installed is increased or decreased. According to the measured data of the change in the width of the leaf, four or six baffles are used in the tank, and the width of the plate is from 1/12 to 1/10, which is most ideal for improving the stirring efficiency.

The king of the agitator-type fermentation equipment is required to stir the vapor body to mix the fresh medium components, air and mycelium to achieve the mass transfer and heat transfer effect. At present, there are three basic forms of agitators: flat leaves (straight leaves), curved leaves, and arrow leaves. The curved leaves are used in the equipment provided by our factory. The curved-blade worm wheel agitator has a shearing effect on the fermentation steam, and the fermentation steam flows in the axial direction and the axial direction. Compared with the straight-blade worm wheel agitator, the curved blade is stirred under the same diameter, rotation speed, and leaf width. The power consumed by the device is small, but the effect is very good, and it has been widely adopted in China.

In terms of motor configuration, we use Y-type motors (horizontal type) and YJL type motors (vertical type). Vertical motors are usually used for nominal volumes below 15 m3. Horizontal motors can also be used.

The tank topping is also very important for the fermenter. According to our experience over the years, the design of the take-over position is reasonable, and the operation of the workers is convenient. The size of the take-over is calculated. If the user has specific requirements, it can be negotiated. For special specifications, our factory can be designed separately.

|

Nominal Volume (m3) |

Inner Cylinder Diameter (Dg) |

Height (H) |

Heat Exchange Area (m2) |

Mixing Shaft Speed(r.p.m) | Mixing Shaft Power(kw) |

| 10 | 1800 | 3800 | 14 | 160-260 | 17-22 |

| 15 | 2000 | 4800 | 18 | 166-260 | 22-30 |

| 20 | 2200 | 5000 | 22 | 180-260 | 30-37 |

| 30 | 2400 | 6600 | 34 | 150-250 | 45-55 |

| 40 | 2600 | 7500 | 45 | 150-250 | 55-75 |

| 50 | 2800 | 8000 | 58 | 150-250 | 55-90 |

| 60 | 3000 | 8300 | 65 | 150-250 | 60-115 |

| 75 | 3200 | 8800 | 84 | 150-250 | 90-145 |

| 100 | 3600 | 9400 | 114 | 150-250 | 120-125 |

| 150 | 4200 | 10800 | 165 | 150-250 | 165-275 |

| 200 | 4600 | 11500 | 220 | 140-240 | 215-360 |

Main technical parameters of seed tank

|

Nominal Volume (m3) |

Inner Cylinder Diameter (Dg) |

Height (H) |

Jacket Diameter (Dg) |

Mixing Shaft Speed (r.p.m) |

Mixing Shaft Power (kw) |

| 0.05 | 300 | 700 | 400 | 300-350 | 0.55 |

| 0.1 | 400 | 800 | 500 | 300-350 | 0.75-1.1 |

| 0.2 | 500 | 1000 | 600 | 280-340 | 0.75-1.5 |

| 0.3 | 550 | 1200 | 650 | 280-340 | 1.1-1.5 |

| 0.5 | 600 | 1650 | 700 | 280-320 | 1.5-2.2 |

| 0.8 | 800 | 1600 | 900 | 200-280 | 2.2-5.5 |

| 1.0 | 800 | 1900 | 900 | 200-280 | 2.2-5.5 |

| 1.2 | 900 | 1800 | 1000 | 200-280 | 3-7.5 |

| 1.5 | 900 | 2200 | 1000 | 200-280 | 3-7.5 |

| 2.0 | 1000 | 2500 | 1100 | 200-260 | 4-11 |

| 3.0 | 1200 | 2600 | 1300 | 200-260 | 5.5-11 |

| 4.0 | 1300 | 3000 | 1400 | 200-220 | 7.5-15 |

| 5.0 | 1400 | 3200 | 1500 | 180-220 | 7.5-18.5 |

Related Products