our branch

Wuxi Zhongyue Petrochemical Equipment Co., Ltd.

Hubei Xianglong Chemical Equipment Engineering Co., Ltd.

Hongda Steel Im& Ex Co., Ltd.

HOT NEWS

-

Industrial waste gas treatment recovery unit solution

-

How to filter and dry three-in-one equipment

-

Industrial waste gas pollution hazards and treatment

-

Jinjiang Chemical 100,000 tons / year n-butyl acrylate cooperation project

-

Electroplating wastewater treatment

-

What are the classifications of industrial wastewater?

-

Microbial treatment technology for industrial waste gas

-

Zero discharge treatment technology for desulfurization wastewater

-

High concentration ammonia nitrogen wastewater treatment technology

-

Factors affecting the treatment of waste gas in the chemical industry

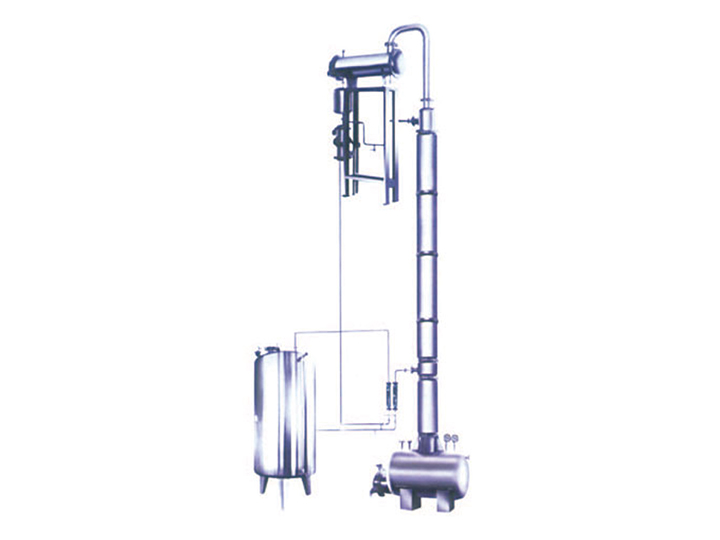

Tower/Filler

Position:HOME > PRODUCTS >Pharmaceutical and chemical equipment > Tower/Filler >

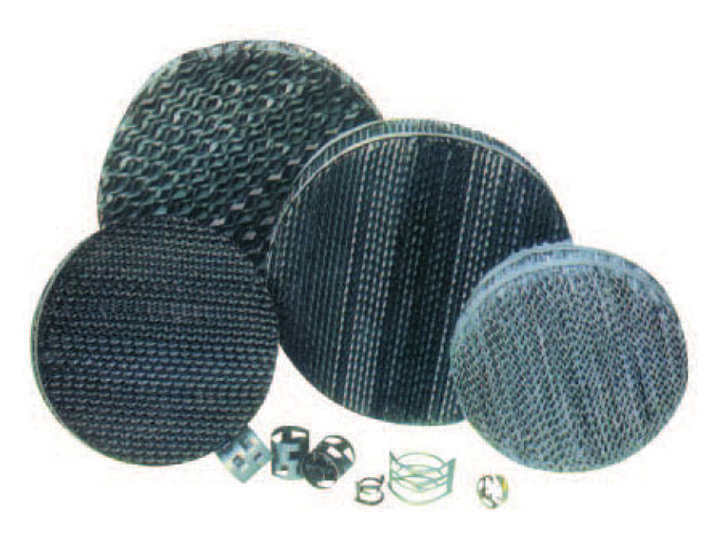

Corrugated filler

Under the guidance of Shanghai Chemical Industry Research Institute, our factory specializes in the production of new high-efficiency corrugated structured filler and random filler. It can be made of stainless steel, copper, aluminum, pure titanium, molybdenum and titanium. It has a wide range of functions in the fields of spices, pesticides, fine chemicals and petrochemicals.

The structured filler is divided into extra mesh, wire mesh, orifice plate, calendaring plate and the like.

The bulk filler are mainly: metal Pall ring filler, metal step ring filler, metal ring saddle, i.e. metal Intras filler.

The structured filler is divided into extra mesh, wire mesh, orifice plate, calendaring plate and the like.

The bulk filler are mainly: metal Pall ring filler, metal step ring filler, metal ring saddle, i.e. metal Intras filler.

SW type mesh corrugated filler geometric characteristic parameters

| Model | Materia |

Height H mm |

Specific surface area m2/m3 |

Hydraulic diameter Ah mm |

Slope |

Void ratio % |

F factor m/skg/m2 |

Theoretical tray No/m |

Pressure drop mmHG/m |

| Type SW-1 | Stainless steel | 4.5 | 643 | 5.7 | 45 | 91.6 | 1.4-2.2 | 6-8 | 2-3.5 |

| Type SW-2 | 6.5 | 450 | 9 | 30 | 95.5 | 1.5 | 4-5 | 1.6-1.8 |

Wire mesh corrugated filler material geometric characteristic parameter SC=CY SB=BX

| Model | Material |

Height H mm |

Specific surface area m2/m3 |

Hydraulic diameter Ah mm |

Slope |

Void ratio % |

F factor m/skg/m2 |

Theoretical tray No/m |

Pressure drop mmHG/m |

| CY | Stainless steel | 4.3 | 700 | 5 | 45 | 87-90 | 1.3-2.4 | 6-9 | 5 |

| BX | 6.3 | 500 | 7.3 | 30 | 95 | 2-2.4 | 4-5 | 1.5 |

Orifice plate corrugated packing geometric characteristic parameters

| Model | Material |

Height H mm |

Specific surface area m2/m3 |

Hydraulic diameter Ah mm |

Slope |

Void ratio % |

F factor m/skg/m2 |

Theoretical tray No/m |

Pressure drop mmHG/m |

| SM125 | Stainless steel | 24 | 125 | 35 | 45 | 98.5 | 3 | 1-1.2 | 1.5 |

| SM225 | 12 | 250 | 15.8 | 45 | 97 | 2.6 | 2-3 | 1.5-2 | |

| SM325 | 8 | 350 | 12 | 45 | 95 | 2 | 3.5-4 | 1.5 | |

| SM425 | 6.5 | 450 | 9 | 45 | 93 | 1.5 | 3-1 | 1.8 |

Metal Pall ring geometric characteristic parameters

| Model nominal size |

Size d×h×δ |

Stacked number n/m3 |

Stacked weight rpkg/m3 |

Specific surface area a m2/m3 |

Void ratio % |

Dry filler factor a/m-1 |

| Dg16 | 16×16×0.8 | 14300 | 216 | 239 | 0.928 | 299 |

| Dg25 | 25×25×0.5 | 55900 | 427 | 219 | 0.934 | 269 |

| Dg38 | 38×38×0.6 | 13000 | 365 | 129 | 0.945 | 153 |

| Dg50 | 50×50×1 | 6500 | 395 | 112.3 | 0.949 | 131 |

| Dg76 | 76×76×1.2 | 1860 | 313 | 0.95 |