our branch

Wuxi Zhongyue Petrochemical Equipment Co., Ltd.

Hubei Xianglong Chemical Equipment Engineering Co., Ltd.

Hongda Steel Im& Ex Co., Ltd.

HOT NEWS

-

Industrial waste gas treatment recovery unit solution

-

How to filter and dry three-in-one equipment

-

Industrial waste gas pollution hazards and treatment

-

Jinjiang Chemical 100,000 tons / year n-butyl acrylate cooperation project

-

Electroplating wastewater treatment

-

What are the classifications of industrial wastewater?

-

Microbial treatment technology for industrial waste gas

-

Zero discharge treatment technology for desulfurization wastewater

-

High concentration ammonia nitrogen wastewater treatment technology

-

Factors affecting the treatment of waste gas in the chemical industry

Industrial waste gas RTO

Position:HOME > PRODUCTS >Environmental > Industrial waste gas RTO >

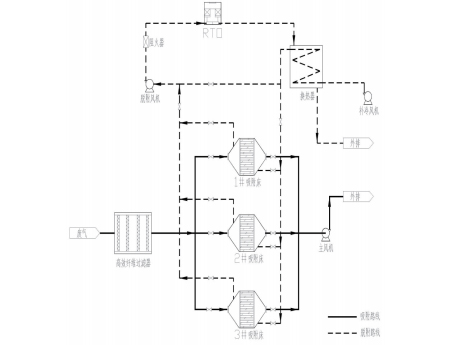

RTO

Application

Oil and chemical (such as plastics, rubber, synthetic fiber, organic chemicals) paint production and painting, printing (including printing iron, printing paper, printing plastics), electronic components and wires, pesticides and dyes, medicine, picture tubes, film, tape and so on. The organic waste gas concentration is between 100PPM and 20,000 PPM.

Principle introduction

Oil and chemical (such as plastics, rubber, synthetic fiber, organic chemicals) paint production and painting, printing (including printing iron, printing paper, printing plastics), electronic components and wires, pesticides and dyes, medicine, picture tubes, film, tape and so on. The organic waste gas concentration is between 100PPM and 20,000 PPM.

Principle introduction

Regenerative Thermal Oxidizer (RTO) is an energy-saving environmental protection device for treating low and medium concentrations of volatile organic waste gas. The principle of the regenerative thermal oxidizer is that the activated carbon is used to adsorb and concentrate the low-concentration organic waste gas. After the adsorption is nearly saturated, the hot air is introduced to heat the activated carbon, so that the organic waste gas is desorbed to oxidize the combustible waste gas to the corresponding oxide and water at a high temperature. Thereby purifying the exhaust gas and recovering the heat released when the exhaust gas is decomposed. The decomposition efficiency of the exhaust gas is over 99%, and the heat recovery efficiency is over 80%.

Structural feature

1. Low operating costs and ultra-low fuel costs. When the organic waste gas concentration is above 450 PPM, the ruler O device does not need to add auxiliary fuel.

2. The purification rate is high, the two-bed ruler O purification rate is above 98%, and the three-bed RTO purification rate is above 99%.

3. Does not produce secondary pollution such as NOx.

4. Fully automatic control and easy operation.

5. High security.

2. The purification rate is high, the two-bed ruler O purification rate is above 98%, and the three-bed RTO purification rate is above 99%.

3. Does not produce secondary pollution such as NOx.

4. Fully automatic control and easy operation.

5. High security.

Suitable for the treatment of the following organic waste gases

1. Large air volume and low concentration;

2. On the same production line, the composition of exhaust gas often changes due to different products;

3. The exhaust gas contains components such as mercury, lead, tin, zinc, etc., and phosphorus, phosphide, arsenic, etc., which are present in the exhaust gas, and cover the surface of the catalyst to increase the catalyst. Loss of activity; the presence of halogen and a large amount of water vapor temporarily deactivates the catalyst).

Performance characteristics。

2. On the same production line, the composition of exhaust gas often changes due to different products;

3. The exhaust gas contains components such as mercury, lead, tin, zinc, etc., and phosphorus, phosphide, arsenic, etc., which are present in the exhaust gas, and cover the surface of the catalyst to increase the catalyst. Loss of activity; the presence of halogen and a large amount of water vapor temporarily deactivates the catalyst).

Performance characteristics。

1. Low operating cost and reasonable price/performance ratio.

2. High purification efficiency, VOC removal rate ≥95%, up to 99%.

3. Long service life and easy maintenance.

4. The operation is safe and reliable.

5. Easy to operate and high degree of automation.

2. High purification efficiency, VOC removal rate ≥95%, up to 99%.

3. Long service life and easy maintenance.

4. The operation is safe and reliable.

5. Easy to operate and high degree of automation.

Related Products