our branch

Wuxi Zhongyue Petrochemical Equipment Co., Ltd.

Hubei Xianglong Chemical Equipment Engineering Co., Ltd.

Hongda Steel Im& Ex Co., Ltd.

HOT NEWS

-

Industrial waste gas treatment recovery unit solution

-

How to filter and dry three-in-one equipment

-

Industrial waste gas pollution hazards and treatment

-

Jinjiang Chemical 100,000 tons / year n-butyl acrylate cooperation project

-

Electroplating wastewater treatment

-

What are the classifications of industrial wastewater?

-

Microbial treatment technology for industrial waste gas

-

Zero discharge treatment technology for desulfurization wastewater

-

High concentration ammonia nitrogen wastewater treatment technology

-

Factors affecting the treatment of waste gas in the chemical industry

Dry mixing equipment

Position:HOME > PRODUCTS >Pharmaceutical and chemical equipment > Dry mixing equipment >

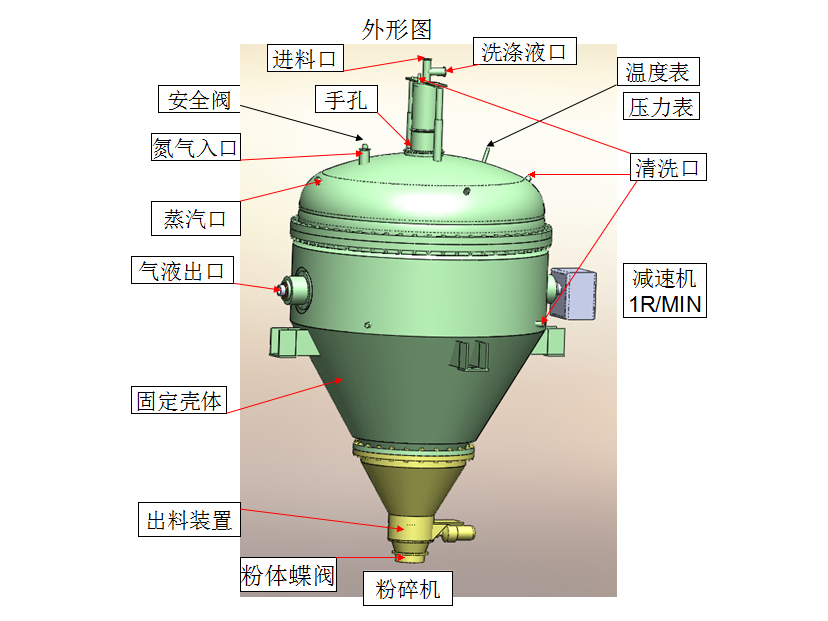

Sanitary screw belt vacuum dryer

The spiral belt vacuum dryer is a high-efficiency multifunctional full-closed vertical vacuum drying equipment that integrates drying and mixing. Its drying efficiency is 3~5 times that of the same specification "double cone rotary vacuum dryer".

Structural features and functions

Structural features and functions

The internal heating of the ribbon increases the overall heating area of the device by 30%.

The spiral belt vacuum dryer can achieve the effect of bottom-up cycle agitation, and can obtain efficient forced heat transfer performance. When the material filling rate is 30%~100%, 100% heating can be obtained. Suitable for mixing and drying fine materials.

Fully enclosed system, no foreign matter pollution, high cleanliness, especially suitable for mixing and drying of sterile biological products and medicines.

The gap between the ribbon vacuum dryer and the wall of the container tube is small, which can effectively prevent the material from sticking to the surface of the wall.

The small-angle cone-shaped cylinder structure makes the discharge speed fast, clean and no accumulation. Tank and discharge valves enable in-line cleaning (CIP) and in-line sterilization (SIP).

The device has compact structure, stable operation, good sealing, no lubrication leakage, easy operation and long service life.

Working principle

The spiral belt vacuum dryer can achieve the effect of bottom-up cycle agitation, and can obtain efficient forced heat transfer performance. When the material filling rate is 30%~100%, 100% heating can be obtained. Suitable for mixing and drying fine materials.

Fully enclosed system, no foreign matter pollution, high cleanliness, especially suitable for mixing and drying of sterile biological products and medicines.

The gap between the ribbon vacuum dryer and the wall of the container tube is small, which can effectively prevent the material from sticking to the surface of the wall.

The small-angle cone-shaped cylinder structure makes the discharge speed fast, clean and no accumulation. Tank and discharge valves enable in-line cleaning (CIP) and in-line sterilization (SIP).

The device has compact structure, stable operation, good sealing, no lubrication leakage, easy operation and long service life.

This machine is made of explosion-proof motor, driven by FAF series parallel helical gear reducer, which drives the belt agitator to rotate. The animal material rotates along the cone wall and rises from bottom to top. After the material reaches the highest point, it is driven by gravity and inertia. The center of the vortex returns to the bottom of the cone-shaped cylinder. A series of processes force the material to be heated in the cone-shaped cylinder, interdiffusion, convection, shearing, misalignment and blending, so that the material can be repetitively reciprocated in all directions. The high-frequency heat exchange of the ribbon and the wall surface of the cylinder achieves the effect of heating dry noise in a short time.