our branch

Wuxi Zhongyue Petrochemical Equipment Co., Ltd.

Hubei Xianglong Chemical Equipment Engineering Co., Ltd.

Hongda Steel Im& Ex Co., Ltd.

HOT NEWS

-

Industrial waste gas treatment recovery unit solution

-

How to filter and dry three-in-one equipment

-

Industrial waste gas pollution hazards and treatment

-

Jinjiang Chemical 100,000 tons / year n-butyl acrylate cooperation project

-

Electroplating wastewater treatment

-

What are the classifications of industrial wastewater?

-

Microbial treatment technology for industrial waste gas

-

Zero discharge treatment technology for desulfurization wastewater

-

High concentration ammonia nitrogen wastewater treatment technology

-

Factors affecting the treatment of waste gas in the chemical industry

Dry mixing equipment

Position:HOME > PRODUCTS >Pharmaceutical and chemical equipment > Dry mixing equipment >

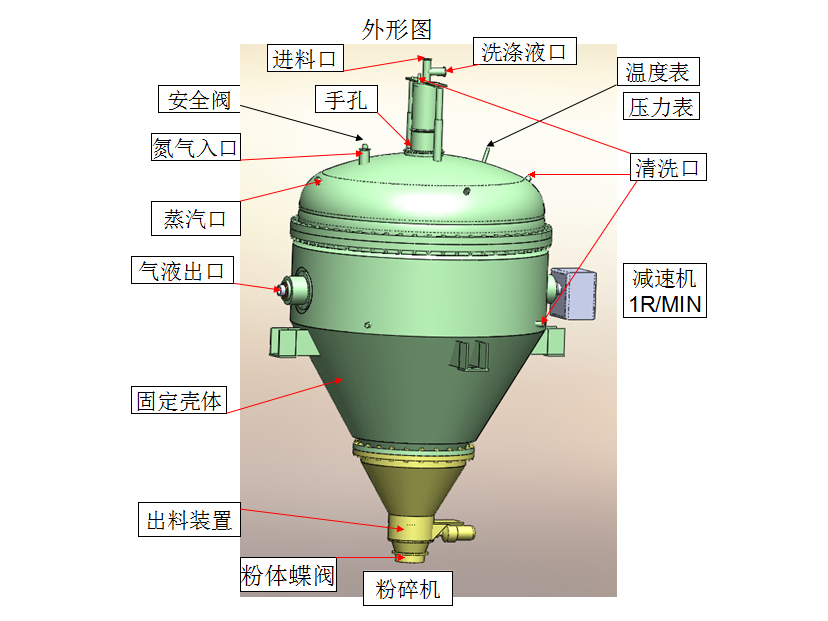

Filtering, washing and drying three-in-one equipment

The filtering, washing and drying "three-in-one" equipment can simultaneously filter, wash and dry in the same equipment instead of filtering and drying equipment (such as suction filter, pressure filter, double cone dryer, drying oven, etc.). Solid discharge process. Widely used in medicine, chemical, pesticide, food and other industries, it is the best equipment for filtration and drying. It can realize continuous operation and full-process continuous operation, and is more suitable for the production of aseptic products and toxic products.

Filtering stage

Separation of the filter cake and mother liquor of the product. The filter cake can be up to 500mm thick.

Washing stage

The dewatering and drying treatment of the filter cake, while the filter cake is scraped loosely by the agitator, the side wall of the device, the bottom of the filter plate, and the moving stirring blade simultaneously heat the filter cake, and the moisture portion is quickly evaporated to achieve a drying effect. The vacuum method in the device accelerates the evaporation rate, and the evaporated moisture is taken away by adding the treated hot nitrogen medium to accelerate the drying of the material and improve the drying effect.

Filtering stage

Separation of the filter cake and mother liquor of the product. The filter cake can be up to 500mm thick.

Washing stage

The dewatering and drying treatment of the filter cake, while the filter cake is scraped loosely by the agitator, the side wall of the device, the bottom of the filter plate, and the moving stirring blade simultaneously heat the filter cake, and the moisture portion is quickly evaporated to achieve a drying effect. The vacuum method in the device accelerates the evaporation rate, and the evaporated moisture is taken away by adding the treated hot nitrogen medium to accelerate the drying of the material and improve the drying effect.

Drying stage

The filter cake was further purified, and the residual mother liquor was washed and dehydrated. The filter cake and the washing liquid were mixed layer by layer by means of a lifting agitator, and finally formed into a slurry, and the suspension cake was sufficiently washed.

Filter material

Metal sintered or filter cloth (can be selected from 5um to 50um according to user needs).

Filter cloth dead corner margin

25mm unilateral

Flatness of single-sided bottom plate

±1mm/m

a. The fixed chassis is soldered to the device and has a heating system for heat drying.

b. Detachable chassis: Clamp the upper and lower flanges with a clamp to achieve sealing. The chassis can be disassembled and grounded with a hydraulic cylinder. The lower part of the chassis has wheels for moving to clean the filter plate. The chassis is driven by a heating system, one is a flow channel type, and the other is a pipe heating type. The filter plate is bolted from under the chassis to make the filter plate flat and there is no bolt in contact with the product.

Unloading stage

The dry material is automatically discharged from the side discharge port through the reverse rotation of the s-type agitating slurry, and directly enters the package.

a. Stirring forward and reverse rotation:

After the motor is reduced by the motor reducer, the shaft is rotated. The adjustment of the speed is achieved quickly by frequency conversion.

The hydraulic motor is powered by the hydraulic motor to drive the shaft to rotate, the rotation speed is regulated by the regulating valve, and the stirring lifting chassis is lifted and powered by the hydraulic pump on the hydraulic station. Pump station control is available in manual, electronic and pneumatic control.

b. The reducer adopts the German SEW company product.

c. Speed: Control by 0-20 rpm by inverter, including safety prevention device.

Main features

Energy saving: low motor power (speed reducer ratio I = 46.3)

Set in place cleaning, in-situ sampling, steam sterilization (122 ° C)

The lower chassis and the simplified connection are double-channel inclined seals, and the “GMP” design with no dead angle is suitable for disinfection and cleaning. Achieve a perfect seal and form a good fit.

Reduce the labor intensity of operators and prevent product contamination, and more adapt to the "GMP" requirements.

Product Specifications

The filter cake was further purified, and the residual mother liquor was washed and dehydrated. The filter cake and the washing liquid were mixed layer by layer by means of a lifting agitator, and finally formed into a slurry, and the suspension cake was sufficiently washed.

Filter material

Metal sintered or filter cloth (can be selected from 5um to 50um according to user needs).

Filter cloth dead corner margin

25mm unilateral

Flatness of single-sided bottom plate

±1mm/m

a. The fixed chassis is soldered to the device and has a heating system for heat drying.

b. Detachable chassis: Clamp the upper and lower flanges with a clamp to achieve sealing. The chassis can be disassembled and grounded with a hydraulic cylinder. The lower part of the chassis has wheels for moving to clean the filter plate. The chassis is driven by a heating system, one is a flow channel type, and the other is a pipe heating type. The filter plate is bolted from under the chassis to make the filter plate flat and there is no bolt in contact with the product.

Unloading stage

The dry material is automatically discharged from the side discharge port through the reverse rotation of the s-type agitating slurry, and directly enters the package.

a. Stirring forward and reverse rotation:

After the motor is reduced by the motor reducer, the shaft is rotated. The adjustment of the speed is achieved quickly by frequency conversion.

The hydraulic motor is powered by the hydraulic motor to drive the shaft to rotate, the rotation speed is regulated by the regulating valve, and the stirring lifting chassis is lifted and powered by the hydraulic pump on the hydraulic station. Pump station control is available in manual, electronic and pneumatic control.

b. The reducer adopts the German SEW company product.

c. Speed: Control by 0-20 rpm by inverter, including safety prevention device.

Main features

Energy saving: low motor power (speed reducer ratio I = 46.3)

Set in place cleaning, in-situ sampling, steam sterilization (122 ° C)

The lower chassis and the simplified connection are double-channel inclined seals, and the “GMP” design with no dead angle is suitable for disinfection and cleaning. Achieve a perfect seal and form a good fit.

Reduce the labor intensity of operators and prevent product contamination, and more adapt to the "GMP" requirements.

Product Specifications

| Product specifications | Φ1000 | Φ1200 | Φ1400 | Φ1600 | Φ1800 | Φ2000 | Φ2400 | Φ2800 | Φ3000 |

| Volume (m³) | 1.2 | 1.5 | 2.2 | 3 | 3.5 | 4 | 6 | 9.5 | 10.2 |

| Filtration area (㎡) | 0.8 | 1 | 1.5 | 2 | 2.5 | 3 | 4.5 | 6 | 7 |

| Stirring stroke (mm) | 300 | 300 | 400 | 400 | 400 | 400 | 450 | 450 | 500 |

| Motor Power (kw) | 5.5 | 5.5 | 7.5 | 7.5 | 11 | 11 | 15 | 18.5 | 22 |